(Story)

m/c history

project

events

Hardware

Software

People

Media

Support

Future

Links-

The ICT 1301 Resurrection Project.

The Project Diaries

( or BLOGS, if you insist! )So what is News this Edition!

A major fault with the machine, looked as if the OPEN DAY was going to have to be cancelled, but

we managed to pull the machine back in time to deliver over 7 hours of public viewing.

Below is all the gorey detail !Here in reverse Chronological Order are the diaries for

2009 right back to 2003, when we started.

Episode 114:- 5th August 2009

Today it is time to return to the primary aims of the project and work on the high speed transfer interface resumed. Signals that last year were giving us problems are now linked in via co-axial cables and we are seeing signs of success ! The machine ran from about 13.00 to 17:00 whilst we worked on the resolution to the interface problems. At any point in time we were expecting the old problem to return, but by close of play the machine was still running well. The only thing that got caught today was brought in by the cat who lives on the farm, looks as if his hunting skills are better than ours.Episode 113:- 22nd July 2009

This day started with us setting up a way of identiying just what caused the pre open day problems.We have now made it possible to isolate every branch of the failing signal in an attempt to find the cause of the problem. Its just a big logic mouse trap and we are awaiting the return of the problem to cure it once and for all.

The day closed with a full run of the machine and although 5 decks were possible we limited the run to 4 and all the peri's we could fire up! But the problem did not return, so we left our big mouse trap set up for another day !

Episode 112:- 12th July 2009

Up early and out the door at 06:30 to ensure the event goes off.However I nearly stopped the open day happening, as having set some caution tapes to mark off an area, I ducked under the tape to exit and cut my head. The medical help was rapid and effective which meant we only started a little later than usual. But it does mean that we can add real blood to the effort today !

" Link to the 2009 Open Day Page "

Thanks to Stuart Fyfe, Morgan, and all who showed up to support us on the day

including some of the original engineers, always a real pleasure to meet up and talk over old times.

hard to say how many people visited but estimated at over 310

Episode 111:- 8th July 2009

Pre open day nerves are starting to show and its all hands to the pumps to finalise the setup. News today is that we have a ring main installed around the machine, to feed test gear and lighting, also we have an extractor fan!Whilst working on the surrounding area today we monitored the power supply that failed on the 1st and it stayed steady all day long !

Episode 110:- 3st July 2009

Well today is a special day, the open day is close and we do not have a working machine to show the public, so I am here at the project trying to fathom out two things !1. What has happened after the ' Burnup ' we suffered 2 days ago ?

2. How can we get the machine back to a point where we can at least load and run programs ?

So a check of all the connections showed that no shorts could be found, and further that all the signal levels were connected. A check of the power however showed a miss match between the minus 6.3volt (a) supply and the minus 6.3volt (b) supply ? had this got too far out of spec and blown the a board in bay 11 ??

1's stream bistable in 5A8 - cr's ok now , but only a few orders could be obeyed !

digging further the machine is stopping too early to terminate long functions

After much chasing of our own tails we worked back to the board that had burnt up, and discovered that it consisted of two elements. The other element in the board used to replace the damaged board was defective ! ( ever get the feeling you cannot win sometimes ? )

Now at least a larger set of functions run to completion! And we may just have enough CPU to run the OPEN DAY after all. ( Phew ! )

Episode 109:- 1st July 2009

After loading my car up with items for the openday on the 12th I was a little later than usual arriving at the project, but as I entered I could hear the machine running as Roger worked on the demo program. He was working on the code that produces the clearwrite paper tape that the machine produces for the visitors. I unloaded my car and started going through a checklist of items we may need.All seemed to be going well and after the last visit the prospects for the event were looking good. The day was quite hot and walking outside to review the layout of the entrance area I needed a good sunhat on, however on returning to the machine a whiff of hot paxolin greeted me, I shouted to Roger 'Something Hot' and we started sniffing like mad and moving around to isolate the source. Our noses agreed that it was coming from bay 6 and as that is one of the main CPU bays the power was turned off, the covers removed from both sides of the CPU and we isolated the lingering smell to logic Rack B.

No sign of any discoloured components could be seen, but access here is limited and the boards are very tightly packed together. Eventually we had to turn the power back on and try to locate the source again, we had got close and the package in Bay 6, Logic Rack C position ?? proved to be the culprit. A small inductor was grossly COOKED and BLACKENED, thinking that we had got lucky we replaced the board and powered up with caution, only to be greeted with the same effect after a 90 second period.

where it dumped current into the CPU logic.

We had a short circuit somewhere in the heart of the CPU, whatever the problem the output on pin 25 of this package was bieng damaged. So it was into the Wiring and Address books and the signal seemed to go to lots of places. Putting together a list of outgoing connections we isolated 5 signals to the far end of the CPU and tried again, with the same whiff of death from our logic with in about 90 seconds. Another try found 3 more connections listed, and still the problem remained.

Now we were sure we had got all of the destinations of the signal isolated we had to start considering a wiring short somewhere. A meter showed that the outgoing pin read very close to a short circuit to earth and we left the meter connected and started unsoldering connections as the signal moved from bay to bay. At last with the link disconneted between bay 5 and bay 11 the short vanished, so we knew it was on the outgoing side somewhere in bay 11 and the only valid destination in that bay had the pin already isolated.

We were now faced with removing the complete logic rack which housed the board, not an easy job to undertake in the somewhat stifulling heat but there was no other option. Removing the 50 or so wrapped connections freed off the rack and it was fully withdrawn, taken outside and examined in the bright sunlight. It may be a disappointment to you dear reader, as well as to the both of us but no sign of any short could be found, the rack was vacuumed cleaned and after the odd bit of bird dropping was removed and given another close visual inspection. A test with the meter showed that the fault no loger existed, a further test showed that the short was not in the remaining CPU so it had vanished. A few short, sharp four letter words may have escaped our lips at this point, which may have reflected the reference to bird droppings above. Inspection of the bay with the Rack removed shed no more light on what the cause of the short may have been, but did show some more of the dreaded birds nest which gave us problems many years ago.

After we assured ourselves that we had cleared the problem, ( and the birds nest ) we started to put the rack back together, a slower process than removal and carefully checking each step as it was a tight fit with multiple connections on both the left, right, top and bottom of the rack. So some 90 mins later we had the rack back in place and powered the machine back up and started sniffing like mad for about 5 mins until we felt we could detect no trace of further burning. Then it was time to reconnect all of the isolated signals and try to run the machine, flossie seemed to power up ok, but we soon discovered the we were now suffering from another problem, the control registers were getting corrupted when moving between Control register two and one. At first the 4 bits were gaining and we isolated that to a bistable in ?? which was changed, on the next power up the 4 bits were good but the 1 bits started failing, which had been good before.

A long time was spent trying to understand the new fault with reference to what we had just done, the logic in bay 11 is all to do with clock counting from the drum and it does inpact on the control registers in that the current drum address can be transfered into the control registers during an update half way through a drum transfer. Did we have a problem that was modifying the control registers when it should not ??? . We decided to let the machine cool down and will check the state of play early tommorrow morning, during this time the Audio/Visuals for the open day were checked and at least we have the information prepered for visitors.

I left quite late, after 19:00 hours and it seemed that we had gone from a working machine at about 12:00 hours to a broken machine a few hot and sweaty hours later. At this point the open day is not going to happen as we do not have a machine to demonstrate. ( ALL PART OF THE JOY AND TEARS OF COMPUTER CONSERVATION ) I told myself as I drove home, and muttered a few 4 letter words just to let off a little steam. The day closed for me with good news as I was very late back and my dinner had not been fed to the dog, but only because we do not have a Dog !

Episode 108:- 24th June 2009

The project today is getting close to completing the preparation for the open day and at first some work was undertaken tracking down the signals from the card punch, and after a half days work the card puch could read all eighty brushes, most of the problems were down to broken wires between the punch and the input logic rack where the contents of the card are read after punching to check the validity of the data.The last item on the Punch was the contactor again ( this has haunted us for a few years on and off ) but this time a small securing screw was found to be loose in the magnetic hoop used to pull the contactor points into place, another fix to a long term problem, we hope.

We then moved on to the magnetic tape decks and I worked on one or two of the decks whilst we execercised the CPU with the latest verison of the demo program. Our line up of eight decks has given us the probability of starting the open day with 5 of the decks working, which is a considerable improvement on the 2 or 3 we have had in the past. The execessive use of the decks may be a problem though as the heat given off will raise the temperature quite rapidly, and with only small fans at cooling at present we will have to be cautious.

Episode 107:- 17th June 2009

The next item today was to try to find out what the state of play was with deck F, this deck seems to behave in a strange way and to investigate we had to reach the back of the deck. So it was into the power supply from the rear, accessed by dropping down into the area from the top, and the first thing we found was that the deck had been modified ?Eventually we found the diagram for the changes made by Galdor and a quick shorting link allowed the deck to not only run up but we could read data from it, after the pinch rollers were setup ! So we are approaching 3 decks working after the big shuffle around over the winter of 2008.

Episode 106:- 3rd June 2009

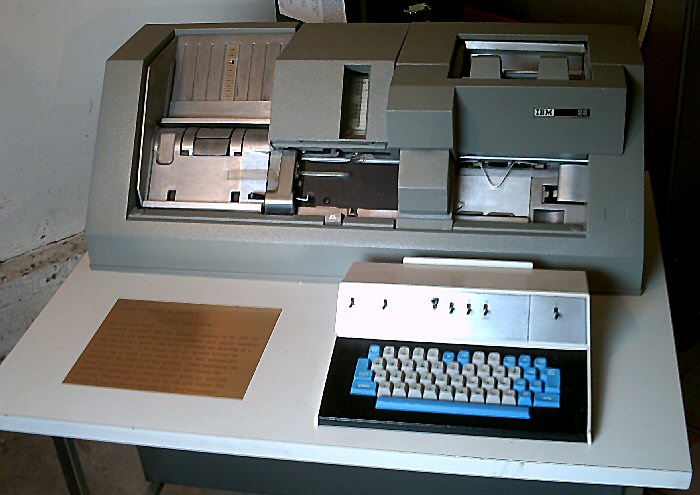

With a line up of eight decks we started to work along the problems these presented, the actual cable connections had to be established and we have two reliable decks out of eight in a line. Unfortunatly deck C was working well and our best deck so far, but now it runs away on read and implies a deck logic problem which will require the whole CPU to resolve, and fault find. Apart from some signal lines which need to be fault found the work on the Card Punch has improved the reliability considerably. The unit is now responding to program control and almost seems to be a fully functional unit.Episode 105:- 3rd June 2009 2009

We are having extra lighting installed today so whilst awaiting this I changed roles due to the delivery of an IBM 029 Key Punch all the way from US of A, so putting my old Data Processing Enginers hat on we started to tackle the problems of getting a 110volt a/c 60hz key punch running on english 250volt 50hz mains. Fortunately the manual came with the machine and we soon found that we could change the mains input strapping to accept 250 volts. As I first try it was logical move, the transformer strappings implied that the 110volt motor would hang off of a winding as if it was an auto transformer. Having made the changes we all moved well away from the machine and flipped the mains on and off again quickly and 'Yes' it blew the fuse in the plug.Head scratching followed and the diagram was reconsulted, after a while we convinced ourselves that the motor was getting 250volts not 110, so we could strap the transformer but not the motor ! Was this another brick wall ? Roger vanished and returned with most ( but not all ) of the card bed from an IBM verifier, but it included a 250volt motor which although it was a little larger looked as if it would fit on the 029's frame.

Now we were left with the 48volt relay supply which was quite happy to settle at 41(ish) volts. However this was enough to allow the mechanism to feed cards and if we were lucky it would space cards along the bed, but only sometimes and very intermittently.

Information suppled from the 1401 project suggested that the Resonant Transformer design of the Power supply was excellent at stabilising a supply, they have several in the 1401 and they work well. This is true if the mains is 60hz US standard but not UK 50hz !

However enough works so that we could remove some problems and could confirm that this was going to be a superb addition to the projects collection. Also work continued and the mechanism had old punched card chads removed and parts of the machine freed up after its long transatlantic journey. There still remains the issue of the relay supply but we will try to resolve that in due time. Another gain from the work today was the addition of extra lighting as Richard fitted up two lights to improve illumination in the work area.

104th Episode:- 20th May 2009 2009

Today we recovered from the Visit on the 12th and the first item was to repair a magnetic tape hub, which had failed during the Demo laid on for our visitors. The next item was to load and run ' Images ' of store test packs, these images were supplied by ACONINT many years ago, and it was with much relief that tests such as AA10/11 loaded via Rogers Serial Boot Loader and ran. We continued with the B tests and the C series covering the CPU and order code. We do have a failure on Sterling functions which we have not investigated, but we have a lot more confidence now some of the official tests have run successfully.Further work today was to set the card reader to reject each card and not to try to use the upward stacker, we will be reading card packs soon and we do not wish to risk crunching up cards in this stacker.

Then we moved onto the Card Punch and in trying to set up the CAM timings we first checked the Continously Rotating cams and hit problems with respecified timings which were only penciled onto diagrams. Both the settings and the modifications were a little vague and we even had to replace one cams arm as it was damaged, the cam itself ( as it was worn )

After that problem we moved onto the Cluched Cams, these only rotate whilst the mechanism is transporting cards. Try as we might we were unable to make sense of the huge errors we were getting with these cam timings, eventually the penny dropped that the gear train driving the cams was out of step with the main gearbox timing, by moving the cam timing shaft one tooth relative to the main mechanism most of the timings fell into spec. However these timings still need to be set correctly and we just ran out of time today.

103rd Episode:- 12th May2009 2009

and also the Computer Conservation Society Visit.

The whole day is on its own page here :-

The 12th May 2009 Computer Conservation Visit

102nd Episode:- 6th May 2009 2009

-

-

Another problem for today was the inability to get the alarm to sound when the machine was in stopped mode. The red light came on but not a sound from the monitor speaker, various logic boards were changed and the problem was starting to look silly as basic logic rules were failing. We started to suspect the clock speed as the machine had been used for a long while on variable not true DRUM speed clock, sure enough the clock had sneaked higher than one mhz, the scope said about 1.075 mhz. I have made a note to bring a frequency meter next visit !

101st Episode:- 22nd April 2009 2009

Today was the return to work on Deck E which has a very funny fault and again is looking like power supply failure ( this time the -24 volts ). Despite many attempts today the deck still fires actuator drive valves randomly.100th Episode:- 8th April 2009 2009

Issues in order today were Mag Tape deck D was failing to drive tapes, after much chasing the 400 volt line to the Actuator was found to be bad. This in turn was chased down to a failed (leaky ) Capacitor in the power supply. Once again a spare was available and after much careful work the deck was restored to life.We then moved on to Deck E which has a very funny fault and again is looking like power supply failure ( this time the -24 volts ). The day finished with a quick investigation into a missing column 2 from the Card Punch Sensing brushes, Time ran out but Roger confirmed that over the Easter weekend that a broken wire had been repaired. Also that he had succeeded in starting to get the serial bootstrap working at 9,600 baud, well done Roger.

The day finished with us agreeing that the April edition of the site would reflect that we had moved from 91 to 93 percent on the original Aims and that we were now moving forward again for 2009.

99th Episode:- 25th March 2009

First item today is the failure of the machine to run Multiply commands when cold. The machine actually locks up, after a lot of scope tracing of logic levels when the machine locks we found that the output of the mill ( adder ) was giving a randon insertion of 2 bits. Logic baord in found to be on temporary rubber connector, OOpppss ! looks like we forgot this from last year.Also another problem isolated where Digit 5 bit 2 was dropping out of the C Register, Logic board changed and problem solved.

Work by Roger after I departed today also showed a problem with the 1300 assembler used to prepare the punched tapes. Once that was fixed we had clocked up 4 fixes today, so good progress all round.

98th Episode:- 3rd March 2009

Much work on the Card Punch, this has been overlooked whilst we worked on other devices. The Main Motor drive contactor, has been cleaned up and adjusted, the strange status problem where the Punch would not become ready was ' eventually ' traced to a defective realy coil ( Relay 12 ) A new coil was fitted and now we were able to continue fault finding.Next problem was a maladjusted ( Card In Hopper ) switch. Now we can load cards, make the unit ready and may be able to read cards as well. But one last problem with a small PCB which is designed to power the punch motor down after about 120 seconds, No spares for this, and we finished the day giving up on this fix.

A short attempt to adjust the Paper tape reader head just proved we had a few more problems, system still not run a multiply command without locking up most of the time.

97th Episode:- 28th Febuary 2009

Roger's logsWhilst waiting for the computer room to come up to 55F I re-seated the punch die block, reconnected Decks B and E to their own electronics and swapped the four thyrotron valves in deck E to see if that solved the problem.

I tried deck E and it seemed worse. The large EL C3J valve lit up at random intervals making the sound of intense arcing. This is the only valve I had not changed. Back to deck B, loaded a tape and tried reading it. This time it mechanically went through the motions but is slow motion!

I tried another read, a couple of backspaces and reads, a rewind and an unload. All in slow motion and incorrect data being DMAed into the core store. The I noticed the vacuum motor was not sucking - I had forgotten deck B has long had a minor problem. A quick tap on the relay and all worked great, so after all there was not anything wrong with deck B's electronics after all. Maybe removing and replacing the plugs in the drum junction had fixed the fault.

I tried out the punch program once again and found the CPU was stopping with an IAS to CR (core memory to control register) error on loading the word 410115584105. Seems to be objecting to the data itself. I stored zero in word zero and jumped to it, no problem. I stored 9 and then 5 in there and both gave errors on the jump. maybe something to do with the parity checking or with the detector for digits greater than 9, i.e. hex A to F.

I connected deck C to the electronics of deck E and it worked perfectly, so we have two working decks, nearly back to where we were before all the upheaval.

I looked in behind the punch control panel and discovered a broken 6v bulb in the 'hopper nearly empty' and no bulb at all in 'stacker nearly full'. I put new 6v bulbs in both but neither lit up when I operated the micro-switches manually. Suspecting a power supply problem, I looked at the punch's PCU and NO lights were on, but the voltage variation showed all voltages were present. Put in three new bulbs and still nothing. Turned out they were all blown, but then I did only pay about 3p each for them on eBay. The next three were all fine. The pilot bulb of the 3v supply worked, the stacked nearly full worked but the hopper nearly empty light did not, seems like a problem elsewhere. The other PSU bulbs also replaced, all OK except the minus 20v (A) which seems to have no power to the lamp holder, maybe the dropper resistor is open circuit.

96th Episode:- 25th Febuary 2009

Roger's logsI managed to do a little more on Flossie today.

Two weeks ago one of the decks made a burning smell, though I can't remember which. Whilst waiting for for the temperature to get up to 55F I risked the decks without Flossie at the official 50F limit.

I can tell you that not only has deck E had a tape mounted on it for the last 30 years but that the upper pinch roller has been activated all that time. The reason for the smell could be the fact that the capstan drive belt had been stuck to its rollers and so the drive motor could not turn. The aluminium of the belt tensioning pulley and the small roller had white rusted to the belt. A little force allowed it to turn by hand. The motor started and then the belt stuck again. Turning it by hand for a few full revolutions and it seemed a bit more free. I tried the motor again and it stalled again but then with a shower of aluminium oxide it came back to life and ran well. The vacuum motor sucked the tape up and the swing arms activated and all seemed well mechanically. Electrically the pinch rollers would not move and when pushed on manually, the spool motors would not move. Maybe it need some power from Flossie to make this work.

Later it was warm enough to power up Flossie. Deck E then responded to a backspace command, though it then lit its overload light. Resetting the overload between operations and I could then read, backspace and rewind, though I stopped it before the start of tape just in case, as the other decks would not go forward at all. Mulling things over I decided to plug our most promising deck (B) into our most promising deck electronics (E). On powering up again, deck B broke the splice of the leader tape to the main tape. Worth another try I thought. I loaded another tape and this time deck B would read, backspace rewind and unload. I know writing would not work. I did not check the data read in detail but there were the customary Cs and Ds in the tape label block and it finished with Fs so all in all it looks like after all the upheaval, we have ONE working deck and set of deck electronics with which we can hopefully debug the other decks and sets of electronics (and possibly connecting cables) by using the known good parts.

I moved on to the card punch reading facility. My program was still in core and I noticed the bug which had caused it to run continuously instead of reading a single card. In keying in the program manually I had got one address field wrong. I used my test card reversed to test the other columns. It looks like columns 30 is stuck at zero but possibly I wrote the results down wrongly. I set it up to continuously read cards whilst I looked at the signal from the column 2 which is definitely stuck as a one. The punch wrecked before I could get to the 'scope. I removed the wrecked card by pulling the die out but after putting it back the punch would not start no matter what I tried. No chance to double check the results I wrote down earlier. Time to turn off for the day and seek Rod's advice, or as a last resort I suppose I could find the operator's manual and read it :-)

95th Episode:- 22nd Febuary 2009

Roger's logsJust a note to say what I've been doing with Flossie.

I have bought some wedge lamps, 32 x 24v yellow, 37 x 17v orange and they came with 15 x 6v grey ones, all for 7.20 which is not bad for the rare 17v ones alone.

I have also picked up seven boxes of 14.5 by 11 listing paper, 70 gsm

I was thinking about the white plastic boxes I have been using for spares. They have clear plastic tops. I realised I could use one drawer of the plans chest to hold a load of them so I would then be able to see what's in them all at a glance. One box had a seized hinge and the top broke off. In moving the stuff to another box, under the other stuff (capstan drive belts) I found a polythene bag with tiny little oblong cubes, if you know what I mean, each with two terminals and some with yellow dots.

These might be the card reader photo cells or paper tape ones maybe.

I have spent some more time unfolding the technical drawings and putting them in the plans chest. It sounds like a quick job but there are SO many drawings you soon get a back ache. I also glance at the drawings and sometimes learn something new. Today there was a drawing of the punch which was specific for two machines, it said London University ICT serial No 6, GEC serial No 7 and Rothams ICT serial No 8 and GEC serial No 12. So that's one more serial number identified. The customer list says the Rothmans machine went to Australia. Surprising that it was practical to export such an early machine, says a lot about ICT field engineering's organisational abilities.

By the time the computer room was warm enough, I had just under 3 hours to use Flossie. The core was OK apart from one bit consistently a one in every word of barn door 2 but I didn't need words 400 to 799. I had punched a paper tape (on my Mac) of a program I wanted to run to be loaded using the minimal 3 word bootstrap. It would not load. I don't think it was the tape because there were about four different places where it stopped in the reader. I could not see anything wrong when I stepped through the bootstrap. Maybe it was still too cold. Maybe the CPU maybe the reader.

I powered up drum one and it did produce a clock, so attaching drum 3 has not messed that up. Initial orders did not work. Reading a single decade, the first instruction was OK but the rest seemed to be messed up. I hand keyed a small program to read one card through the card punch check read brushes, in preparation for reading cards with non standard card codes. After the customary knock of the contactor with handle of a hammer, the punch sprang to life and read a whole deck of cards, though it was only supposed to read one card into core. Anyway I arranged for a card with data on it to be the last but two card in a deck and let it stop at the end of the deck, so the test data was left in core. I noted down the pattern in core and shut Flossie down. Afterwards I found that most of the data was correct, though because I fed the card the wrong way, columns 1 to 33 were blank hence not tested except that column two always read as a one.

Remembering that back in the early 1970s, when the operators told me my deck of cards could no longer be read by the computer, they advised me to use an old fashioned card reproducer to copy my cards. I think the old machine used similar technology to Flossie's punch and had no problem at all so the punch might be a more reliable way to read old cards that through Flossie's proper card reader.

94th Episode:- Febuary 2009

Roger's logsMore news from Roger that the Mag Tape Decks are showing signs of starting to work again, and the next item in line for action on the 11th of March is the Card Punch !

93nd Episode:- 11th Febuary 2009

Today is the first day that I had seen the results of all of the work undertaken over 2008/2009 winter first hand. The space around Flossie is impressive and the next open day will be a better experience for the visitors, the helpers and Flossie herself as we will be able too cool the room easier. The other event today is the visit of Dr David Hartley and Hamish of the Computer Conservation Society.The Second Computer Conservation Society visit.

After our friend's departed we were able to get Flossie to run and the standard multiply yardstick to check her basic functioning. The year on year improvement is now showing, and we were able to start on the first problem of the year.

The Card reader Read Cell for the '11' position was not working, it was soon traced to a failed transistor on the cell amplifer board in position CRA23. A new (Second Hand) GET872 was soldered into place and solved the problem. Moving on we found that some or all of our Mag Tape decks did not respond, it is however very early in the year and the cold was taking its toll.

Whilst testing all the Mag tape drives one deck in the line had a tape loaded ! In all all Innocence I asked Roger how long the tape had been on the deck. ( thinking about a few days perhaps ? )

The answer came back from Roger, " Oh about Thirty Years I suppose " and that dear reader has to be the punch line of the year from this project, for we are only 3 years away from Flossie's fiftieth birthday !

92nd Episode:- Febuary 2009

Roger's logsStill snow on the ground but Richard and Gordon drove down and we got the card reader moved in slightly closer to the console by taking it off its castors and lowering the jack feet so it fits under a lip on the console. The power supply rack and card punch shifted along with it giving us an extra inch or so between the punch and the magnetic tape drives.

About 60 logic connections between the third drum and the drum junction were soldered up so we should now be able to power up Flossie when we can get the computer room up to 13 degrees C (55 Farenheight).

The covers for drums two and three have not been fitted since Flossie left Surbiton around 1978, and even before that they had been cobbled together out of covers for other units, bits of wood and pop rivets. Most of the hinges and top covers were fitted to the third drum and the doors sorted out for the best fit. The end cover will need a couple of spot welds re-done but it looks OK. The corner cover strip was fitted between drum one and the front drum. We will need to modify drum 2's end cover as it fouls the doors if we use the bolt holes as is. There is a 30mm gap between two of the doors which we will probably fill with a piece of wood painted appropriately. Long term we will want to make some new doors and top covers, especially if we fit a fourth and maybe even a fifth drum.

91st Episode:- January 2009

Roger's logs

Here is a view of the new layout which is the background to the 2009 Openday and the new Workarea.

I wanted to find out what is wrong with the card reader's decoding logic and maybe fix it. With one day of reasonable temperatures forecast I left two fan heaters going overnight. In the morning I put in a third one. By 1:30 p.m. it was up to 57 degrees F (14 C) at the drum junction and 56 at the console.

I turned the card reader to safe, turned the drums off, pressed the on button and got a clock straight away. Checked for smoke, no problem. The printer delay turned the printer on and the print hammers started their usual random firing, gradually reducing to nothing.

I checked the control registers would count, they worked fine. I cleared the core and read it back. About a half a dozen errors. I set every bit and more errors. Every digit 1 bit 1 from 1600 to 1999 failed. I looked at barn door 5 and that bit was on rubbers. Wiggled it a bit and that fault went away.

Later on when fully warmed up, we had a full complement of core memory. Not a bad start to 2009.

I found a card with the normal character set punched in it. Before I started the machine I had put it in the card reader, manually activated the picker knives and turned the machine by hand until the first character was at the main reading position. I hooked the Gould scope up to the output of the '1' row amplifier. Winding the reader back and forth and the signal could be seen changing. I tried to do the same with the '11' row. No change. Tried adjusting the adjusting pot. Still no change. The scope then went wrong. It has just two LEDs illuminated but the CRT was blank. This is the first year I have not brought it in for the winter. What to do now?

I thought I'd try out the Hewlett Packard scope which has not worked for quite a long while. It worked just fine. Neither the '10' or '11' row seem to work, though the working '1' row uses the same amplifier brick. There are a lot of Galdor patches on that part of the PCB carrier so I decided to not go in like a bull in a china shop and think about it a bit. I tried scoping the photo cells outputs but did not see any change there either. I powered up the punch and it still fed cards (after the customary knock on the three phase contactor with a screwdriver handle).

We bolted the third drum onto Flossie and levelled it up. I still have the earth connection, data connections, 3 phase power and the contactor's remote control cable to fit. Then we can at last fit the kick plates and

covers which have been lying around for the last three decades.

I have had an old plans chest in an old (Tudor) barn for many years and never had space to install it in the computer room. It was extracted from the junk in the barn, treated for woodworm, had some restoration work done by my joiner friend, Gordon and been installed in the computer room. Work was started on lining the drawers with vinyl and unfolding Flossie's technical drawings and putting them in the drawers. The drawing should be safer stored flat without the folds wearing away and we have a flat surface on top of the unit large enough to lay the drawings on, or to use as a light duty workbench.

We may also construct a home-brew flatbed scanner on that surface so we can scan all the drawings eventually.

Start of work in 2009

Roger's logs

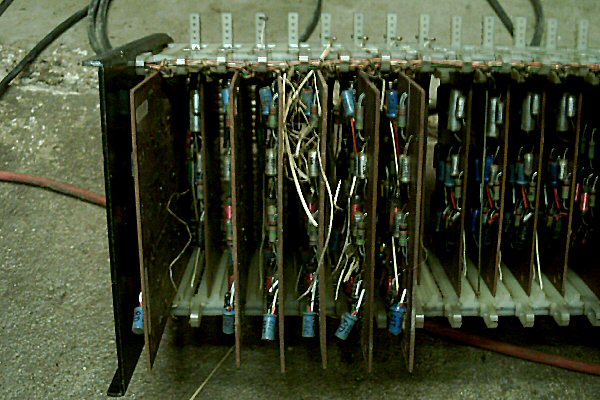

Here are Photo's from this major rework of Flossie's envioronment, this photo shows the Re-Routing of the Data Cables, to the decks.

Yes that is a lot of cables ....

90th Episode:- November / December 2008

Roger's logsArthur was finally moved out. This gave a great opportunity to improve Flossie, the working environment for us and I think, a huge improvement in the experience for visitors and the possibilities for photography. The remains of the old model railway which was being used as a shelf was removed.

All the spare PCB carriers which were stacked on top of the CPU were moved into the other part of the building where the bulk of Arthur had been stored. Much less claustrophobic.

Decks A,B,C and D were moved from the end wall opposite the line printer to the side wall near the card punch. Decks E and F were moved next to them and then an unmarked deck and Arthur's Deck Y which had started to be stripped for spares even before Arthur left the Liverpool Victoria Friendly Society in the 1970s. We then had eight decks in a row, all of which are visible from the same angle as the printer, console and card reader. There were sufficient data cables for all eight decks, some were a bit too long, some a lot too long. All these had to be re-routed and the excess lost without being coiled up. For each deck there had five 37 core cables about 80 feet long, there were eight decks, so there were 5 x 37 x 80 x 8 feet of individually insulated wires inside the outer covers, about 23 miles, enough to reach across the English channel. I would estimate they weight about a third of a ton in total.

When Flossie was installed at Senate House, University of London, the cabling was overhead and entered Flossie through the top cover, and the hole is still there. The cables were attached to the backs of the tape decks with some excess to enable any deck to be pulled forwards for maintenance. The cable were run along the top of a step in the wall and held in place by pieces of steel bar. A trough was constructed from Flossie over a walkway to a roof truss and along this, over the doorway and boxed in next to the door. The plug end of the cables were put through Flossie's top cover with enough just enough slack that any set of cables could be plugged into any set of sockets to enable fault finding of decks, cable sets and 1301 electronics independently. The cables were laid into the trough and through the box (the box cover had not been fitted yet). Excess cabling was held up by specially made supports from Spur shelf uprights so that the cables zig-zagged without being kinked, coiled or rubbed on any sharp edges. A large plywood box about 30 inches high by 10 feet long and four inches deep was built around it.

Some multi drawer shelf units and shelves were bought and much work was done erecting them and rearranging spares into those drawers and onto shelves. In moving Arthur, many vinyl floor tiles had come unglued. Some of them were glued back and an electric polisher used to clean off (most of) the trails of plastic left by the decomposed tyres of the castors of the magnetic tape decks.

The line printer's paper trolley was put back in its rightful place and plugged in.

The card punch was to be moved from behind the power stabiliser to the front. The problem was the gap was too small, so the covers were stripped off. Still not enough room. The heavy power stabiliser rack was held six inches up in the air whilst the punch and its cables were manoeuvred underneath. Done on my own using some large wooden levers trying not to put my hands under the rack.

89th Episode:-September/October 2008

A dehumidifier was bought and will be kept running 24/7.

Flossie (ICT 1301 serial number 6) has for many years shared the barn with Arthur (ICT 1301 serial number 75 with parts of number 159). Arthur has been stored in parts, partly at the far end of the building, and part stacked around Flossie. There was a possibility of Arthur going to the Science Museum in South Kensington but in September hopes of this possibility finally were dashed. Arthur was not now going there, but was still going to move out of their shared barn, you might call it a divorce. Just like a divorce it was difficult to work out what belonged to who. The major units were easy but it was the smaller items which were difficult. Due to lack of space, Flossie had never been fully assembled. Before I brought her to the farm when Flossie was in Surbiton, she had 6 tape drives and 3 drums. Up to this time I had only connected up 4 tape drives and 2 drums. There were also covers, kick plates and top covers which had never been fitted to Flossie. There were also spare parts which were staying with Flossie for a while at least. So the separation was quite complicated.

In preparation for the move, Arthur's card punch was moved to the wall opposite Flossie's card reader and two tape decks were brought in front of the Flossie's line printer. Flossie's punch was mover towards the back of the machine (I just hope I haven't damaged any wires) so that we had sufficient space to extract Arthur's units.

As Flossie has been using Arthur's nameplate (which has the newer ICL name in ICL colours) for many years, a new one was ordered for Flossie, using a picture of Flossie's original one which has the older ICT logo in ICT colours. The new nameplate is a very good copy of the original, it has a slightly thicker frame which I can mill down in due course as well as adding a black spacer behind the aluminium plate which says 1301 so that it appears to float in front of the back board.

Arthur's mag tape control electronics were bolted together so we could identify and bolt on the top covers, doors, end covers, kick plates, corner cover strips, junctions, spacers etc. Then we knew that bays 13 to 22, the tape junction and tape power supply were all complete. The far end was then stripped down, leaving the Data Transfer Units (DTU) intact. We then bolted on the core store, drum electronics and drum to the DTU and did a similar exercise before moving on to the central processor racks and finally the console, printer, reader and punch. I kept finding bits of welded metal I'd forgotten about and spent a while figuring where they fitted into the giant 3D jig-saw.

88th Episode:- July & August 2008

The problem with one track of the paper tape reader not working reliably came back. The problem appeared to be with one of

the multi turn potentiometers in the read head. There are nine of these, eight for the data tracks and one for the

sprocket track. Four of these are of a different type, must have been repaired prior to me acquiring Flossie.

These are not only made by a different manufacturer, they also have a different resistance. They are long narrow items with a tiny adjusting screw in the end and two holes in them which need to be in the right place so that they can be mounted next to each other with a piece of screwed rod through them. I expected to have to adapt the mechanical design in some way to accept a modern equivalent, but on consulting the RS Components catalogue I found one which was not only the right resistance but also the right general shape with a similar screw adjustment. The spacing of the holes was not specified but it was as close as I was going to get. When it arrived and we compared it, it was perfect. Only the terminals were not in line with the originals, but wires bend so not problem. After Rod fitted this and adjusted the screw whilst reading a loop of tape containing alternately hex 55 and hex AA, the reader worked reliably once more.

At last we could get back to the interface we were building. Since the end of 2007 we had rebuilt it (now the Mk 3) with all the integrated circuits in wire wrap sockets and even the transistors in sockets for ease of modification. In the part of Flossie we were connecting to there is a connector which has various signals, the most important ones being Flossie's 1MHz clock and a signal to indicate an I/O transfer is in progress. This is true for 12 clock pulses, during which the B register shifts 12 digits to the right. Output data to the interface shifts out the right most digit (four bits) and it is also possible for input data to be clocked in to the left most digit, though we are not attempting this. The main problem was that after buffering the selection signal through a transistor it was not true for 12 clocks. The start of the signal was not clean enough. We battled with this for a while, tried chokes and got nowhere. We checked where the signal originated and it was fine. We unplugged the interconnecting cable so we could check the actual (buffered in Flossie) signal coming out. It was fine. We found that with the cable plugged in, even with the far end disconnected, the start of the signal was smoothed off. Time for a rethink and we considered various options. We decided that in 2009 we would build a board (the Mk4 interface) which would connect in place of the paper tape punch controller, which is a more modern (1970s) lashed up TTL board. If it works for the punch, it will work for a more general parallel interface made of TTL. It will not be as fast as the Mk3 was intended to be but it will work, though it might mean that the magnetic tape drives will have to start and stop, something we were trying to avoid doing in case the old frail tapes get stretched or broken.

I got my hands on a rack of proper punched card trays, the older type with wire handles. These came from a vehicle coach works which was closing down. Thanks to my niece Debbie who recognised what were using as storage racks and bought them for me. I also got some later type drawers from my old friend Richard Toft who had been using them for storage of parts for the full size Savage steam lorry he is building. All of the ready punched cards were then put in the steel trays. There are still new cards in cardboard boxes but of course these are less precious.

The identifiable card decks, comprising about 80,000 punched cards (excluding duplicates) were then sorted by their ICT subroutine/program designation ready to be read and made available on the Internet. I also annotated a file containing a list of items in ICT's subroutine library with what cards I have got. Hopefully the missing items will be found on magnetic tape in due course. There are a few hundred 160 column cards but if these are ever needed they will have to be read by hand or on a photo scanner and some custom software.

87th Episode:- 13/07/08

There is nowhere to hide for today like it or not it is the" Link to the 2008 Open Day Page "

Thanks to Stuart Fyfe, Morgan, Andy, Steve and all who showed up to support us on the day

including some of the original engineers, always a real pleasure to meet up and talk over old times.

hard to say how many people visited but estimated at over 200

mostly very complimentary and some interesting entries in the comment book

86th Episode:- 09/07/08

After a lot of work the machine was prepared today for the open day, a few last minute panic's as we discovered that some covers did not fit on the Paper Tape Reader. Final excercise was to run the Demo program and although we ran ok! we are planning a fallback if all fails.85th Episode:- 02/07/08

Still in prepare mode today, jobs completed = Tidy up Store unit ( Barndoor 4 ), We also removed and resoldered the control board for Deck D as the solder around the Valvebases to the actuators has lost conntact, probably due to a lot of movement as vavles were changed in the last 45 years. Last item was to add a diode to the 380002 ( read a card command ) and connect it to the 380007 ( Reject a card ) this is to overcome the problems we have with the card stacking mechanism, we are currently routing all cards read into the reject stacker, as a safety move !84th Episode:- 25/06/08

Today its a tidy up and test day. Roger had obtained new transformers for the paper tape reader Clutch and Brake supply, and fitted them to the PSU frame. It was ( smoke tested ) I will rephrase that! Powered up cautiously. and the unit worked well. No sign of overheating, however now we need to find the cause of data bits bieng gained from the tape reader head. A general cleanup of the photo sensor area gave us more reliability, and a reseat of the plug connecting to read head, seemed to cure the gained bit problems.Bouyed up with this progress, the latest version of the demo was loaded and transfered to drum at address 680. Whilst doing this we also backed up the short bootstrap to address 700 on the Drum. A run of this version started well and the machine is performing as it did during its working life. We were obviously feeling too smug, because at that point, Flossie blew a store access PCB, Digit 9 Bit 1 in Barndoor 4. We changed it and then felt very silly as the problem still existed, Why ?? becase we had changed the board in Barndoor 3 not 4.

OOoopppsss!

After that we started again and slowly rebuilt the loading of the devices the machine was driving, and we only needed a small revision to the demo software before we felt that it was ready for the OPEN day. Last action of the day was to adjust the read head now it seemed to have settled down ( Note the setting potentiometer for the track that was gaining earlier seems very Sensitive )

83rd Episode:- 04/06/08

Today all ( or most ) of our problems are with the Paper Tape Reader. We need this unit to load the demo Software and the Main Clutch and Brake Power supply is overheating a transformer. Is the unit pulling too much power or is the transformer failing? We ran the transformer with the load removed and it still started to cook !Looks like a new transformer is required, So after a little more work fixing up a rewind problem with Deck C, we settled down to try to hand key the demo software into the machine, It was a race as the room temperature was rising and eventually it was written to Drum and the machine powered down before it got too hot!

82nd Episode:- 21/05/08

" Ever had one of those days ? "It starts with the french causing a closing down of sections of the M20 due to industrial action on the other side of the channel, then just gets worse.

However in our darkest moments, our spirits were lifted as our efforts today were graced by a Visit from Tilly Blyth who came to visit our project and see what we have been up to. Sorry Flossie was not up to running a full demo for you Tilly, we now think we cooked something when the machine got hot at the end of our 14th May session. So its all hands to the pumps to fix the machine for the open day on Sunday 13th July 2008. At least we have a good demo program now thanks to Roger's hard work over the weekend.

81st Episode:- 14/05/08

Before we started work today we took the time to check out the power supplies around the store ands CPU area. These have not been checked since 2008 switch on, so it was no suprise that both the -6.3 and the +12.6 supplies were both out of specification. It was hoped that this would resolve our problems with the new demo prog, which seemed to be corrupting the main store, but only when tape reads were bieng undertaken.To prove the main store reliability a small program was hand keyed to put a data word into location 50 and move it up the store ( word by word ) to location 1850, this last location was then compared to the original word 50 so when it failed we knew we had a problem.

This proved to be a single core in a single address, something we need to fix, but its a big job so we limited our program to location 1050 and now the test runs without failure. There had been a suspicion that the store was suffering from address problems in every tenth word, Roger had even tried to program around the glitch by jumping over every tenth word in the new Demo Prog.

Now we could focus on the updating of the demonstration program used to show the machine to the public. Roger had done a rewrite to make it more flexible, some progress till Flossie got too hot then we had to close her down.

80 Episode:- 08/05/08

Work today continued on deck B, and it was decided a new relay was required. After much head and hair scrathing( and I do not have a lot to spare )

A new relay was found ( literaly ). The deck may be non standard but it now works , well mostly ! Work moved onto the card reader, and after much logic bashing even that joined in and started to work!

Progress of sorts is always welcome !

We celerbated by mapping what we had stored on the Drum and found a prototype of the Demo program, all good news !

79h Episode:- 30/04/08

Work today focused on Deck B, the unit has had problems for a long while, but it is one of the best and most reliable decks we have ( when it works ). The problem led to a need to pull the deck forward and I dropped from the top of the deck, into the space behind the deck to remove a service cover to access a relay from the back of the unit. When this had been done it was discovered that the deck had been rewired!The relay had been removed from the circuit and the unit rewired to an additional relay which could be accessed from the front of the deck ( Uuuugggg ! )

So not a lot of progress today, apart from testing the main store which had taken place whilst I was getting very dirty and dusty chasing relays !

78h Episode:- 7/04/08

With crossed fingers and a close eye on the thermometer Flossie was powered up today, the machine does have problems. But after about 25 mins most of thr lady joined in, apart from a problem with carrys in the Mill. Now Flossie is a mature lady and does basic arithmetic in Decimal, Sterling and now Binary But the difference between all of them is controlled by ' Fillers ' . When Flossie adds 1 to 9 the answer is 10 but to get the carry to the next hexadecimal digit she adds 6 to the total, that is the Filler value she uses for Decimal working. But Flossie had big problems with this, eventually we found a duff gate package which was replaced and now all is working ok. The day closed with a working CPU and all of the main store running ( work over the years is showing and this machine is getting more reliable, visit by visit.Start of work in 2008

77th Episode:- 25/09/07

I arrived to find that we were having another window replaced, nice to know the air condition is bieng maintained ( read the earlier diaries to get the joke )Our problem from the last episode returned today, so many hours went into discovering that the real problem was a failure of the 68 ( compare ) function. This was chased down to the board in position 6E14, which was on a temporary connector ( a rubber block that pushes the pins together ), fitting the board properly with wrapping wires cured our problem.

We could now move on to the implementation of the interface we need to recover the software from this machine. Various problems were resolved by us changing the logic and tweaking the timing on the interface, eventually we discovered a blown transistor on the board which stopped any further work.

As an aside we have expeienced a few problems with this interface, the earthing is a problem as the logic on flossie is Zero volts to minus 6.3 volts, and the interface is standard TTL, using zero volts to plus 5 volts. By floating the interface at minus 5 volts to the true earth we seem to get the signals balanced, but the minus 1.3 volts difference does give us problems. The earth connections we use are massive when you consider the signals are only about 2 milliamps max current. The transistors are used to cut off this negative swing which TTL cannot tolerate.

I will create a page to explain this interface soon, but getting it working ASAP is our priority at present.

76th Episode:- 12/09/07

The first item today was to keep our store fully functional, and we needed to replace the A7 board in Digit1,Bit2 which had failed since our last episode. We now seem to be having some problems with either the 66 ( increment Function ) or the 28 ( preindex ) function. We worked on this problem, but the symptoms were very intermittent. We were sure that at one point we saw a 66 funtion fail to increment properly. But after reloading the code from drum it seemed to work flawlessly ! The day ended with us feeling a lot more confident with the state of the machine after all the years of work which we have put into it !75th Episode:- 29/08/07

Well today finds us continuing with the work on flossie's memory, for several weeks we have been trying to get the last store module, barn door 4, fully working.First however Roger showed me a new rack that now holds a lot of the boards we have changed over the years. These need repair and we must find some time this winter to put some effort into bench repair of these boards.

So far we have progressed to a point where store module 4 is now basicaly functinal, but with many problems left, we have about 85 percent of this last module working. Fixing this means that for the first time since the project started back in 2003, we now have the possibility of a fully working store and the window on the last phase of our current project opens to allow us to start capturing the software stored on the magnetic tapes.

First problem is a lot of groups of ten addresses which are not functioning so we changed the G6 board in barn door 4 for addrssses 80/180 but to no avail. Digging deeper into the logic we tried the G3 decoder board in 10G20, but the problem persisted. After a lot of head scratching we found another decoder board in 10G22 which seemed to have an input but no output.

Yes! we now have a lot more store working! But we were left with two individual addreses which looked very bad, 118 and 146. Due to the age of this machine a lot of the ' Spare Cores ' have been utilised. These are lines that were built into the Core Stacks, now over 45 years ago, and are used by ' jumpering ' the spare lines into use.

Our approach is to change any external components when we can, as these are current stearing diodes for each of the two thousand words of store. Further both of the defective words were already swopped to 'Spare' lines. After a little more work we had all the 400 words of the module working. This is the first time this module has worked since the project started over five years ago.

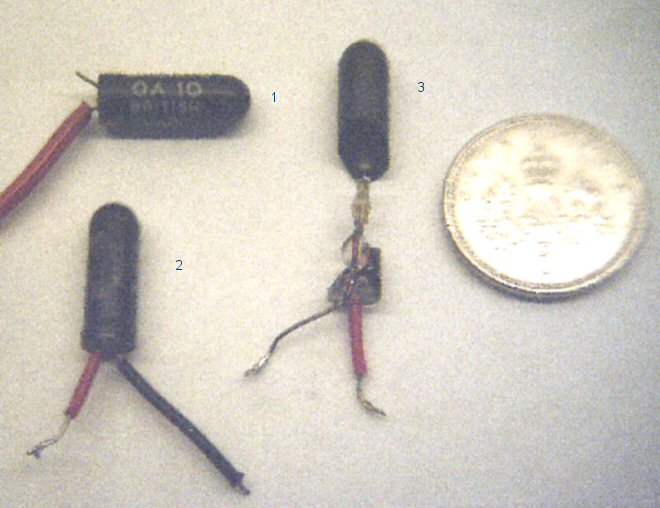

A quick photo of the type of diodes used in the store modules on this machine, Mullard type OA10

key to items

No1 is a diode that has been 'cropped' out to allow a replacment,

No2 is a standard replacement part, second hand of course !

No3 is the type of failure which can occur after over 45 years's, the glass shell has ruptured

and the junction has been exposed to moisture which has degraded the alloy.

The 5 pence coin on the right of the image is for size reference.

For your information:- the whole 5 store modules use at least four thousand of these diodes for stearing the current to where it is needed !

Now we had just one single word in store module 2 which was failing, this has been repaired a few times before. We had changed the current stearing dioes, so were now faced with moving this word to one of our precious spare words. As this was the last problem that stood between us and a fully working store, we had little option but to sacifice another spare, so we jumpered in the spare line in the core plane.

Now we expected a fully working store, and indeed the word did now work and store data, but one bit was now failing Digit 8 Bit 8.

This presented us with another dilema, we had to choose beween rewiring a whole column of 400 cores to the last remaining spare in the module, or consider untried options as we could just crosswire the one failing core plane into an abandoned column which had 40 or 80 words which ' may just be ok ' ?

As we have on old ' Core Stack ' on the bench we were able to check out the the idea. Although it did seem somewhat of a whacky idea, we tried it !

Now even this problem was solved !

But just to prove that flossie does not give up easily, the just repaired store module four developed a new fault, word 140 failed !

After our experiences over the last four visits this was easy to fix by swapping out the failed diode. I also took the chance to tidy up some of the earlier work from previous visits, and our crocodile clip fix from the previous episode was replaced with a properly wired connection.

Now ' AT LAST ' we had a store of two thousand words by 48 bits wide working again ! A milestore event in our five year old project.

A store test was coded up to test the store to ensure we had no lingering problems ( or doubts in our own minds ) the test ran for over an hour whilst we exercised an elderly apple 2 computer from about 1984, as old as this home computer was, Flossie is over twenty years older !

The day ended with us agreeing that we had today passed the 90 percent mark in our journey on this project.

74th Episode:- 14/08/07

Work continues on the defective store module ' barn door 4 ' . This has been physicaly disconnected from the machine power lines in the past as it has blown fuses in the store power supply and pulled the whole machine down! The first thing we noticed was that by comparing the signals on module 4 to the signals on module 2, there were considerable differences. Something was still stealing current from the rest of the module and when ever we addressed the one working word then all the signals looked good. We reduced the problem to a small diagram of the lines of wire running through the core store and the diodes which stear the current to the correct wire when addressed. A lot of time was spent discussing the possibilities, and the only thing which fitted the problem was the fact that a diode had gone short circuit ! but how to prove it ? it was after all ' one diode ' in 800 or more that the module used to address the store.The store module boards recieve logic signals from the machine and convert them to Current levels to either switch or not switch magnetic cores. This means that with the boards connected there will be quite large back circuits if you just meter the core array for resistance. However if we could pull or disconnect the most suspect boards then a meter test would show the problem. So with meter in hand and the 'Suspect' address lines boards disconnected a trip down the 400 individual address lines was started, almost down to the last two stacks out of ten a possible short circuit was found. Eureka !

Now the problem was to convince myself that this was indeed the problem we were looking for! Some considerable time was spent on the bench with our example core stack. A plan was formulated that if I removed two more boards then the possibility of any back circuit was removed. This was done and the short circuit still existed on the store module, but not on the bench reference stack. As this was a diode that had gone short circuit another diode was added in series with the suspect diode and the current robbing problem was solved. Unfortunatley the wiring around the stack was now bieng disturbed and a critical connection wire fell off at this point. A quick link with a crocodile clip cable restored the connection, and allowed testing to continue. We actually have over 70 percent of this store module working now, and just a small celebration was called for.

We have run out of time today but this store module is now showing signs of real life now and all of the work that has gone into it is paying off !

73rd Episode:- 01/08/07

This is the first day after our open day and a lot of time was spent tidying up and clearing the decks for work to continue on the real project. But before we consign the 2007 open day to history we do seem to have made a small quantity of money from our visitor's and Flossie now has enough money in the bank to fund her power for about 300 hours.Many thanks to all who visited us on the open day in 2007 and donated towards this project!

A general test of the state of the machine was done and although flossie did get quite hot on the day we seem to have survived with no new problems.

To restart the work the Defective Store Module No 4 was reconnected, and to prove a point blew the store power supply fuse immediatly !

We disconnected the five power wires which deliver the 22.6 volts feed, and reconnected one at a time after repairing the power supply again. The original problem of the store pulling power relative to the number of bits in the data register still exists.

Word 1167 still playing up in store module 3, so we replaced the stearing diodes again ! Why do they keep failing ?

So now we are left with 4 out of the 5 store modules working ! It is time to reconnect the failing module No 4 and find the power problem that has been around for far too long.

After reconnection we checked the voltage at the power supply and as this supply is tracked by a thermsistor to compensate for temperature, some time was spent ensuring that the supply tracked the correct graph according to the manual. Although we proved this was correct, whilst we waited for the load and temperature to change we ran a simple test of the module and whilst testing all the address lines going into the store, we were very lucky and found a major current source in the read and write logic that was stuck at a half level. It was neither on or off but stuck at a half level. It took two stabs to find the problem but the control board which feeds current to the individual address lines, was found to be defective. Now at last we had found the fault which has plagued the repair of this store module, and blown fuses many times in the past.

A reassesment of the situation however showed that we had many other problems with the store module, of the 400 words only one word seemed to work and all others only worked if the number of bits in the word was limited. In summary the current needed to switch the Cores was biend robbed somewhere!

But at least one word did work and that was better tnan a store that had refused to work at all and blown fuses.

72nd Episode:- 15/07/07

" Link to the 2007 Open Day Page "

Thanks to Stuart Fyfe and Morgan ( and very Nice to see you Olwen ! )

hard to say how many people visited but estimated at over 240

mostly very complimentary and some interesting entries in the comment book

71st Episode:- 11/07/07

Open day prepare = dress up flossie and setup lights/facilitiesA lot of time today was spent tidying up after our long fault finding sessions on the store. Many boards needed to be re-wrapped and conneted properly, as the use of 'tempory' rubber connectors to make a test connection can give more problems than they solve if they are not made good afterwards.

70th Episode:- 04/07/07

Work today focused on the coding for a demonstration program for the open day !The resultant code is stored on drum bands

640 and 860 :- load 810000-200xxx-004000 to run

24 = peri activity

21 = sprag paper feeds

All devices mt2,3,4,pt,cr,cp,lp

69th Episode:- 20/6/07

Roger had worked on the store over the weekend and it had blown the power supply fuse again, we decided to isolate the store unit again, as it may stop the machine on the open day. But before we did that, we have noticed that this store unit has a unique fault. The power surges can be intitiated by just presenting data to the store, we do not even have to write or read the data. Solve this problem and we may be able to fix this last store problem. We do have about 1,200 words of store for the open day demonstrations, and that will surfice.On to the CPU problem, the code which we used last week was still on the drum and the problem seems unchanged, now we could start working on it. A lot of time was needed before we started to suspect the control register update mechanism, this works perfectly until an instruction which uses steps 21 or more is issued then strange things happen in the control registers.

The area around the CR update was scoped, and we could prove more than one update was happening, but only after a long function ( What a Beastly Fault ).

Just to complicate things the machine never fails on manual control, this is a problem which only fails at full speed.

Now Flossie only uses the minimum time to complete any function, some intructions will stop after 12 steps and others take a little longer if they need to write results to store. Termination of functions shorer than the full length cause a reset to be sent to the timing chain, and the timer starts again on the next function. A lot of work was done to prove to ourselves that not only were we getting more than one update per word, but we were also getting duplicated steps from the timing chain ( No wonder we have a problem !)

Continued work isolated a binary which was responsible for step 22, ( 6B11 ) now this should be cleared if a function which is only 21 steps long is issued. But as it was not clearing it was sending a second pulse back into the timer, whilst the next function was bieng obeyd. Resulting in chaos as the machine duplicated steps including updating the control registers, assigning carry bits in the Mill and moving data to and from store.

Much Celebration followed, as we now have a working machine for the open day ( and only three scant working days left to set it all up ).

68th Episode:- 12/6/07

Today was spent wrapping all the boards we swapped in the store on the last visit, about 18 boards in total, a chance was taken to service the hard working wrapping tools at the same time. After this session all of the five store units have all boards wrapped in.The last hour of today was spent on our CPU problems, and although there was no breakthrough a picture of the problem is beginning to show. The machine is jumping out of loops when a long instruction is obeyed, if the instruction is in the first half of a word it takess a long time to break. If the instruction is in the second half it breaks a lot quicker. Just what this means will have to wait till next week, but this at least is a way into this problem at last. I have saved the failing code on to the drum on band address 900, I hope its still there next week when we need it.

Sad news is that our new scope has stopped working, we need this to solve the CPU problem, so next week its the scope first and the computer after.

67th Episode:- 6/6/07

Attention moved on today to to the next store unit Barn door 4, this has had its power supply isolated, as it was blowing the store power supply fuse. A long list of failed baords later and the store unit was not fixed but at last started to give data back. So we can write to the store unit and " Sometimes" we get some of the data back. A lot of the board are on temporary or rubber connectors, a lot of work is needed to tidy this up.We have a new scope to use today it's a 4 trace HP 54501a and a fine tool it is too.

66th Episode:- 23/5/07

Back to the memory problem, the the machine mostly held up today, and we were able to add Barn Door 3 to our list of working memory. Its been a long wait but we now have 1,200 words of contiguous memory ! But it took 4 control boards and 2 data board before we had a fully working store unit.65th Episode:- 08/5/07

We started work on barn doors ( main memory ) only 3 of the store units ( Barn Doors )working out of 5.However we started to suffer from corruption in the control registers, it took a long while to identify the problem ! And any function which has to write away a result after a computation stands a chance of breaking the machine.

Just to complicate the issue the fault seemed to be temperature sensitive as well. It took all day and we are still unsure at the end if we fixed this problem or not !

64th Episode:- 10/4/07

Today we have a new problem the machine seems to freeze when doing a multiply, intermittently ! The first try was to find what was causing the problem and we found that if a packed digit was in the B register then the machine might freeze. A lot of logic is used to decide what is the quickest way do the multiply. So a lot of gates were changed to allow us to find this fault, far too many, as our stock of spare boards is dwidling quickly.Eventually the right board was found and we can run any combination of digits and all now works well.

63rd Episode:- 28/3/07

The 28th of March saw the first visit of of the 2007 work on this project. Work on the mag tapes ( replacing duff lamps ) continued and after some considerable warming up flossie was powered on, ( always a thing we do with crossed fingers, after the hibination period ). Lots did work but, we had to tweak some of the ageing power supplies back to specification, and then we could work on the store problems, much head scratching untill we found a bit in the A register Digit 7 bit 1. Board replaced and now we can talk to as much store as we have working, just 3 out of 5 units to date.We are left with problems with the micro order steps which are stopping the multiply and the drum functions woking, however the investment in time on the Tape control unit has paid dividends. As everything we fixed last year still works, so we only have the write commands to fix and we may be close to all the electronic systems working.

Now the good news *** The Open Day in 2007 will go ahead *** !

Start of work in 2007

2006 Overview.

Well I do wonder what I will return to in 2007, Roger has done a lot of things this year including

fitting a new roof covering, a new window and some of the old ventilator shafts are now bieng taken

out and covered over in the roof space, as they did leak when the rain was heavy ! At least

I am happy that the work we have put into this project so far ( slightly over four years ) will be

safe over winter.

There are plans for this machine's environment but like me, you will just have to wait and see what

happens. I certainly plan to continue and as soon as the weather allows, I will be back to start

the proccess of extracting all that software from this machine.

For all of those who have followed our task over the years ! Thanks !

Next year could see the harvesting of the software we have worked for.

It could also be the start of a brand new project. ;o)

So as they say ! Watch this space !

End of work in 2006

62nd Episode:- 13/12/06

This is the latest date we have worked in any year and the temperature is still on our side. This is the 1301XOUT " last try for 2006 " although we can now connect to the interface and set test conditions, we are experiencing a lot of difficulty getting the decode to work. After a lot of work today we discovered that the levels on the interface are not stable during the length of the 1301 instruction. The control register is moving and changing the levels we are trying to decode.So now we have to resolve this issue, we can either modify the interface or put statisicers on the new 1301XOUT board. So its time to put the covers on Flossie for this year !

61st Episode:- 22/11/06

Testing of the 1301XOUT board could only start after we had cabled the unit up, the first problem was the clock driver from the interface. An add-hoc design which matched the impedence of a standard clock loading was tinkered together, this improved the overall situation. After more work I discovered that I had failed to allow for the inclusion of input resistors to the board from the 1301, we were over driving and perhaps blowing up the transistors which are there to give us clipping and isolation from the difference of the minus 6.3volts and the minus 5volts of the TTL on the board.

60th Episode:- 08/11/06

Repair IAS, address decode problems, and address 788 single word failed, this last item proved to a defective diode which was replaced.Then arrange the best configuration of IAS, it looks as if the best we can get is words 600 through to 1800 about 1200 consecutive words. SO as such Roger will be producing the software to run in this configuration.

Next week we will try to connect the transfer interface which is called the 1310XOUT ( as in Transfer OUT ). It is designed to take 12 digits, by four bits each of data, and throw it into a FIFO, then allow a PC to transfer six by eight bits of data out and file it, transfer speed is going to be important but to start with lets just get it working !

59th Episode:- 15/10/06

We started with a dead Scope, it proved to be a duff filter element, so we just jumpered the connection out !Long slog today, and we can actually Write to a tape, but only sometimes ! Looks like a timimg problem still has us beaten.

58th Episode:- 11/10/06

Most of today was spent decoding how the machine reads tapes in all tracks format ! "WHY" because we may need to read the tapes ourselves. By knowing all the parity bits as well as the data bits we can reconstruct partial failures, the machine can correct single bit errors but multiple errors will need some more computing power to resolve. Although it was a lot of work today, we are confident that all known single bit failures can now be found and that a lot of multiple failures will also be correctable.57th Episode:- 27/09/06

First off today, the good news ! we can still read magnetic tapes !But picking up from where we left off, we cannot write to any deck, the tape does not move and the DTU write control freezes, in a startup stare called "Prepare to Write".

Logic tracking followed, as we worked our way through the multiple interfaces to the tape decks, the address selection logic and the cables and boards to and from the DTU. ( The engineering term is Logic Bashing, moving from pin to pin checking logic levels ).

We then moved to head bashing, as we could not understand why a simple gate would not work. It had only three inputs and they were all moving, eventualy Roger spotted the fact that two input's were complimentary, when one turned on the other turned off so no output, the reason was no write ring on the tape. Ok so now we get an output and trotting all over the DTU we eventualy found 19H7 pin 6 no output we replaced the A4 package and now we get the tape deck's to move. However the DTU locks up in a different state, this time its "Interhead gap". This could be good news as you enter this state to allow the Write order to terminate by giving the freshly written tape a chance to make it to the read head for checking. But you also go this way if the order has failed, so it can complete and report errors.

Ok enough is enough! we checked we could still read tapes ok ! and the battle continues next week.

56th Episode:- 13/09/06 = (In which electronic hiccups lead to a miraculus cure for magnetic malladies.)